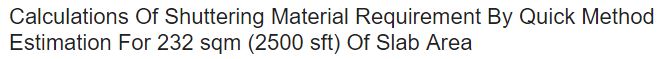

Shuttering Material Requirement

Civil Engineers' Blog

Category: Methods of Measurements

Preparation of Unit rates for finished items of works

Estimation of basement steps (one way)

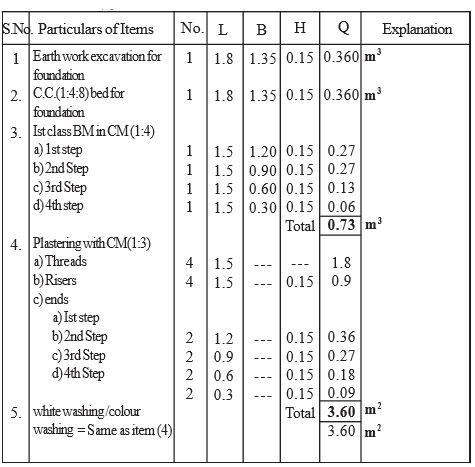

Estimate the Quantities of the pictured roof shown in figure

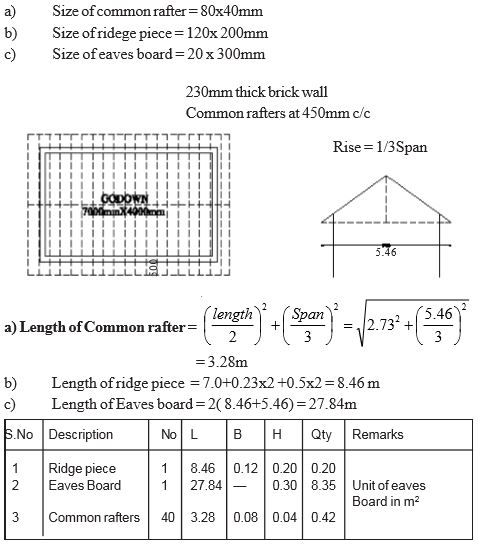

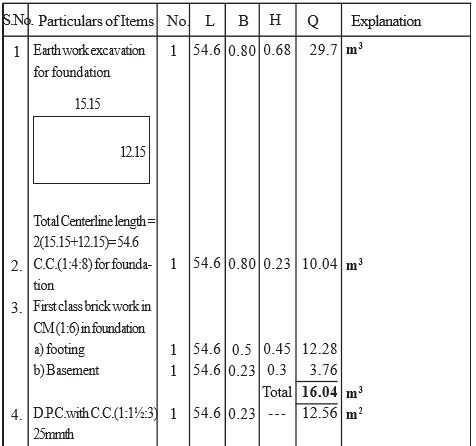

From the given figure below calculate the details estimate for the Compound Wall

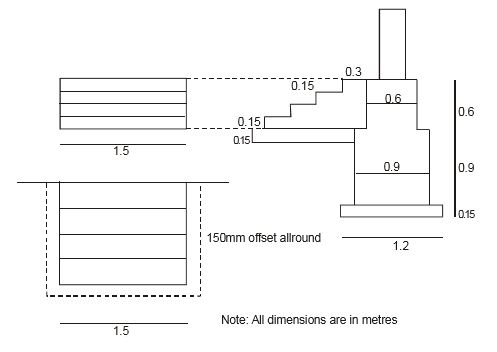

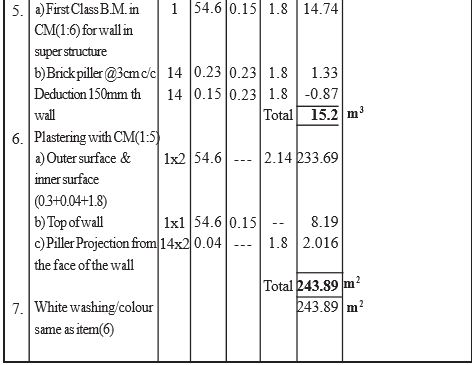

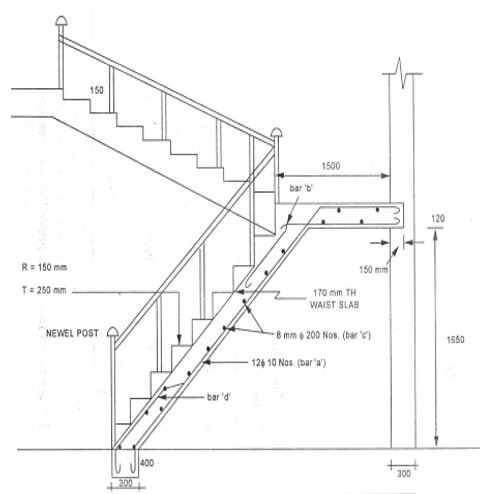

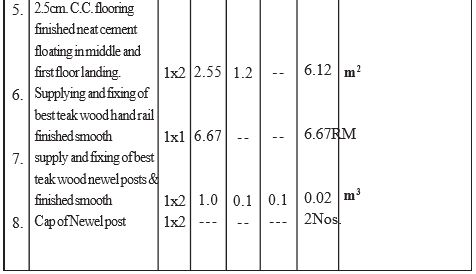

Calculate the quantities of items of the stair case of the figure shown in below.

1. Estimate give an idea of the cost of the work and hence its feasibility can be determined i..e whether the project could be taken up with in the funds available or not.

2. Estimate gives an idea of time required for the completion of the work.

3. Estimate is required to invite the tenders and Quotations and to arrange contract.

4. Estimate is also required to control the expenditure during the execution of work.

5. Estimate decides whether the proposed plan matches the funds available or not.

Estimating involves the following operations:

1. Preparing detailed Estimate.

2. Calculating the rate of each unit of work

3. Preparing abstract of estimate

1. Drawings i.e.plans, elevations, sections etc.

If the drawings are not clear and without complete dimensions the preparation of estimation become very difficult. So, It is very essential before preparing an estimate.

2. Specifications.

a) General Specifications: This gives the nature, quality, class and work and materials in general terms to be used in various parts of wok. It helps no form a general idea of building.

b) Detailed Specifications: These gives the detailed description of the various items of work laying down the Quantities and qualities of materials, their proportions, the method of preparation workmanship and execution of work.

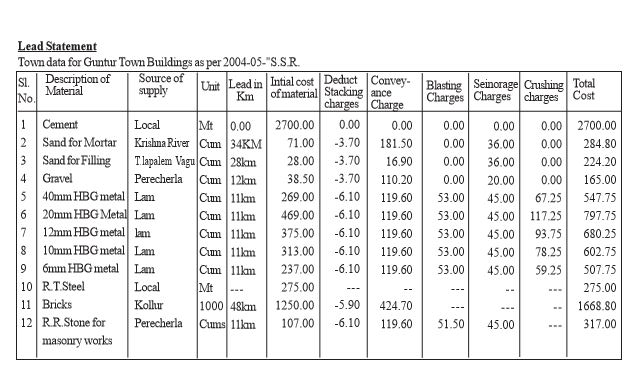

3. Rates

For preparing the estimate the unit rates of each item of work are required.

a) For arriving at the unit rates of each item.

b) The rates of various materials to be used in the construction.

c) The cost of transport materials.

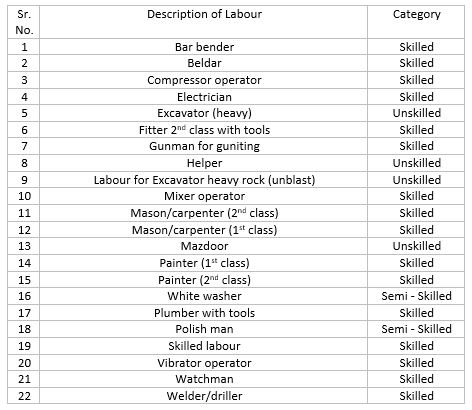

d) The wages of labour, skilled or unskilled of masons, carpenters, Mazdoor, etc.

Most of people think that the estimate of a structure includes cost of land, cost of materials and labour, But many other direct and indirect costs included and is shown below:

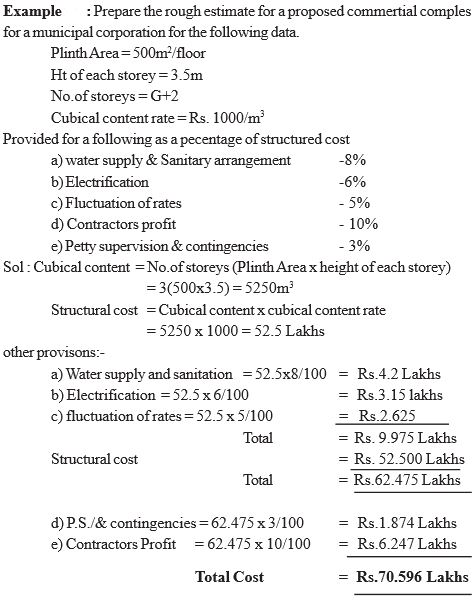

While preparing an estimate, it is not possible to workout in detail in case of petty items. Items other than civil engineering such items are called lump sum items or simply L.S.Items. The following are some of L.S. Items in the estimate.

1. Water supply and sanitary arrangements.

2. Electrical installations like meter, motor, etc.,

3. Architectural features.

4. Contingencies and unforeseen items. In General, certain percentage on the cost of estimation is allotted for the above L.S.Items Even if sub estimates prepared or at the end of execution of work, the actual cost should not exceed the L.S.amounts provided in the main estimate.

During the construction of a project considerable number of skilled supervisors, work assistance, watchmen etc., are employed on temporary basis. The salaries of these persons are drawn from the L.S. amount allotted towards the work charged establishment. that is, establishment which is charged directly to work. an L.S.amount of 1½ to 2% of the estimated cost is provided towards the work charged establishment.

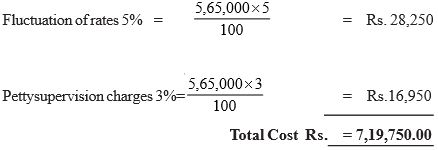

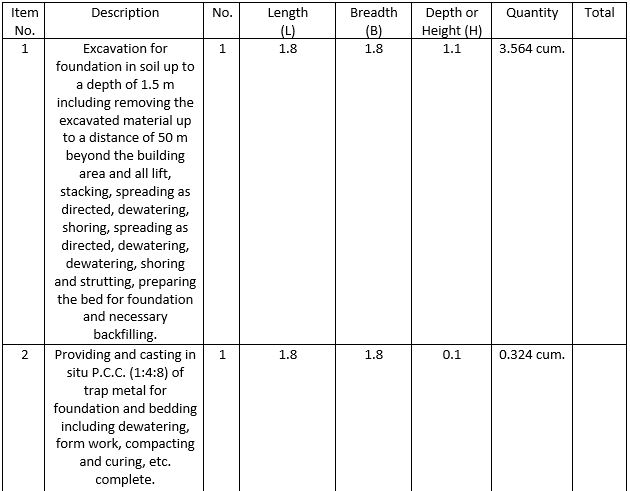

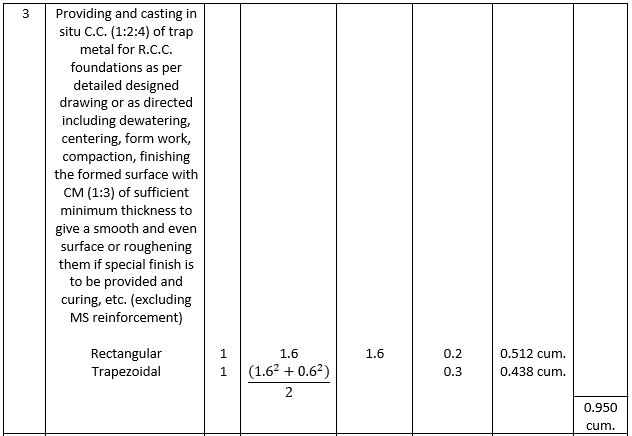

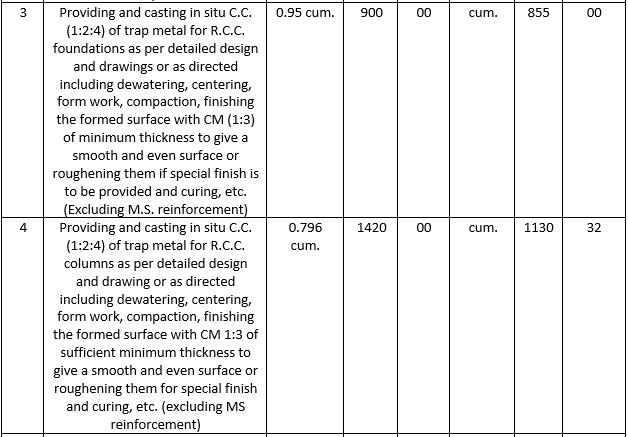

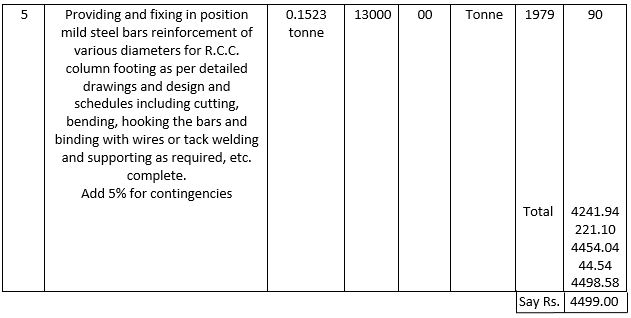

DETAILED ESTIMATE:

The preparation of detailed estimate consists of working out quantities of various items of work and then determine the cost of each item.

This is prepared in two stages.

i) Details of measurements and calculation of quantities: The complete work is divided into various items of work such as earth work concreting, brick work, R.C.C. Plastering etc., The details of measurements are taken from drawings and entered in respective columns of prescribed proforma. the quantities are calculated by multiplying the values that are in numbers column to Depth column as shown below:

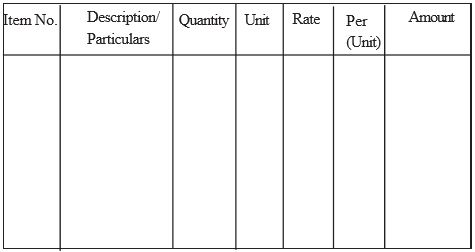

Details of measurements form

ii) Abstract of Estimated Cost : The cost of each item of work is worked out from the quantities that already computed in the details measurement form at workable rate. But the total cost is worked out in the prescribed form is known as abstract of estimated form. 4% of estimated Cost is allowed for Petty Supervision, contingencies and Unforeseen items.

Abstract of estimate form

The detailed estimate should accompanied with

i) Report

ii) Specification

iii) Drawings (plans, elevation, sections)

iv) Design charts and calculations v) Standard schedule of rates.

i) Quantity and transportation of materials: For bigger project, the requirement of materials is more. such bulk volume of materials will be purchased and transported definitely at cheaper rate.

ii) Location of site: The site of work is selected, such that it should reduce damage or in transit during loading, unloading, stocking of materials.

iii) Local labour charges: The skill, suitability and wages of local labourers are considered while preparing the detailed estimate

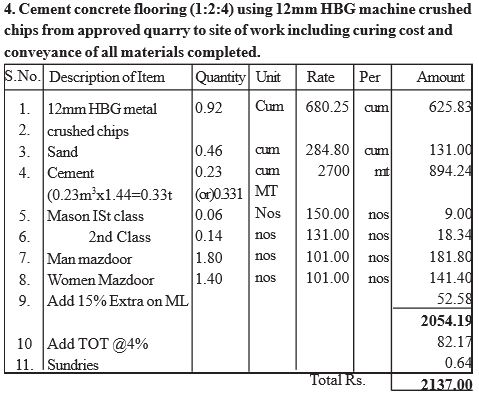

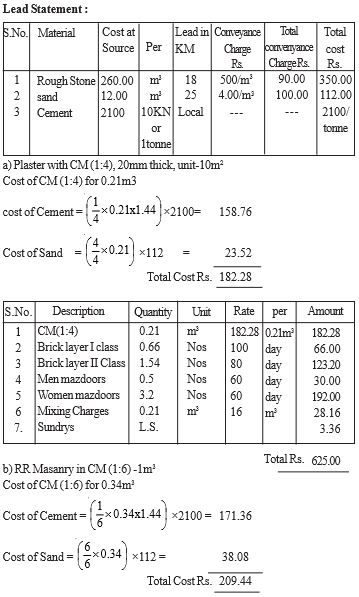

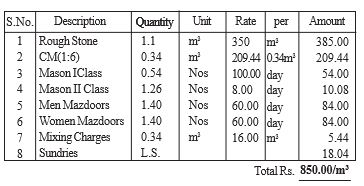

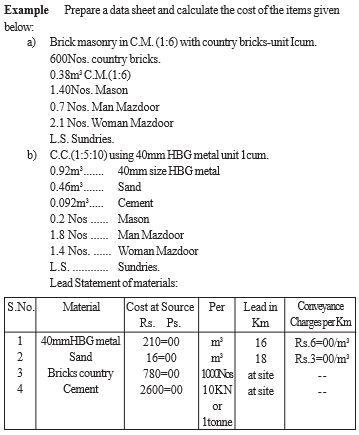

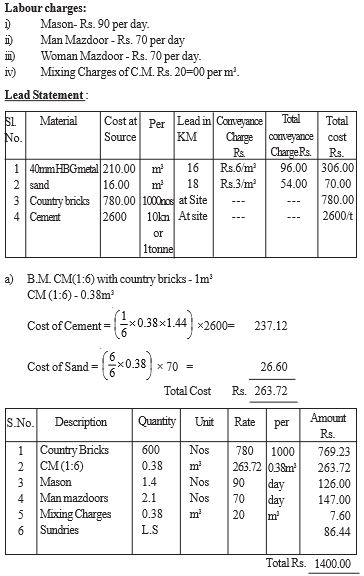

The process of working out the cost or rate per unit of each item is called as Data. In preparation of Data, the rates of materials and labour are obtained from current standard scheduled of rates and while the quantities of materials and labour required for one unit of item are taken from Standard Data Book (S.D.B)

The rate per unit of an item includes the following:

i) Quantity of materials & cost: The requirement of mateials are taken strictly in accordance with standard data book(S.D.B). The cost of these includes first cost, freight, insurance and transportation charges.

ii) Cost of labour: The exact number of labourers required for unit of work and the multiplied by the wages/ day to get of labour for unit item work.

iii) Cost of equipment (T&P): Some works need special type of equipment, tools and plant. In such case, an amount of 1 to 2% of estimated cost is provided.

iv) Overhead charges: To meet expenses of office rent, depreciation of equipment salaries of staff postage, lighting an amount of 4% of estimate cost is allocated.

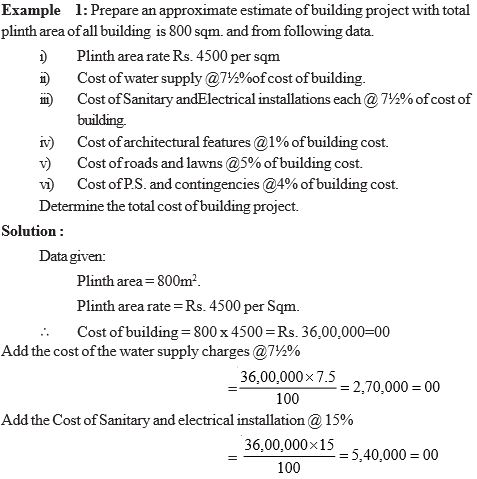

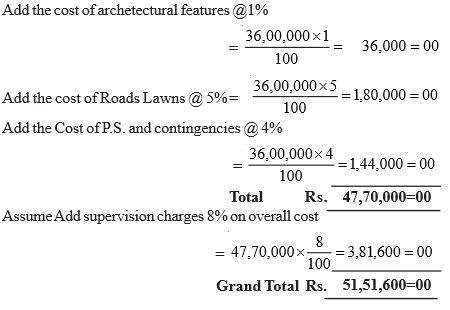

Preliminary or approximate estimate is required for studies of various aspects of work of project and for its administrative approval. It can decide, in case of commercial projects, whether the net income earned justifies the amount invested or not. The approximate estimate is prepared from the practical knowledge and cost of similar works. The estimate is accompanied by a report duly explaining necessity and utility of the project and with a site or layout plan. A percentage 5 to 10% is allowed for contingencies.

The following are the methods used for preparation of approximate estimates.

a) Plinth area method

The cost of construction is determined by multiplying plinth area with plinth area rate. The area is obtained by multiplying length and breadth (outer dimensions of building). In fixing the plinth area rate, careful observation and necessary enquiries are made in respect of quality and quantity aspect of materials and labor, type of foundation, height of building, roof, wood work, fixtures, number of storeys etc.

As per IS 3861-1966, the following areas include while calculating the plinth area of building:

a) Area of walls at floor level.

b) Internal shafts of sanitary installations not exceeding 2.0 sq.m, lifts, air conditioning ducts etc.

c) Area of barsati at terrace level: Barsati means any covered space open on one side constructed on one side constructed on terraced roof which is used as shelter during rainy season.

d) Porches of non cantilever type.

Areas which are not to include

a) Area of lofts.

b) Unenclosed balconies.

c) Architectural bands, cornices etc.

d) Domes, towers projecting above terrace level.

e) Box louvers and vertical sun breakers.

b) Cubical contents methods

This method is generally used for multi-storeyed buildings. It is more accurate than the other two methods viz., plinth area method and unit base method. The cost of a structure is calculated approximately as the total cubical contents (Volume of buildings) multiplied by Local Cubic Rate. The volume of building is obtained by Length x breadth x depth or height. The length and breadth are measured out to out of walls excluding the plinth off set. The cost of string course, cornice, carbelling etc., is neglected. The cost of building= volume of buildings x rate/ unit volume.

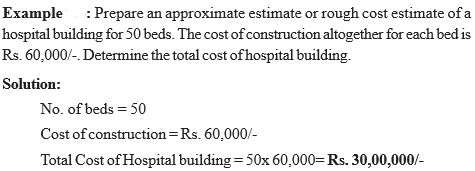

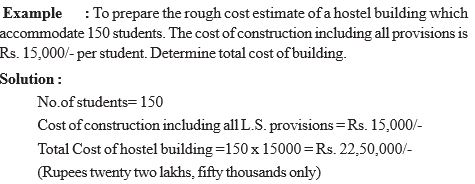

c) Unit base method

According to this method the cost of structure is determined by multiplying the total number of units with unit rate of each item. In case schools and colleges, the unit considered to be as ‘one student’ and in case of hospital, the unit is ‘one bed’. the unit rate is calculated by dividing the actual expenditure incurred or cost of similar building in the nearby locality by the number of units.

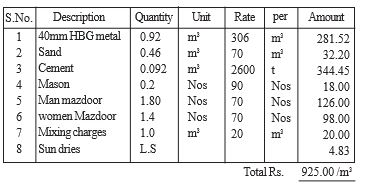

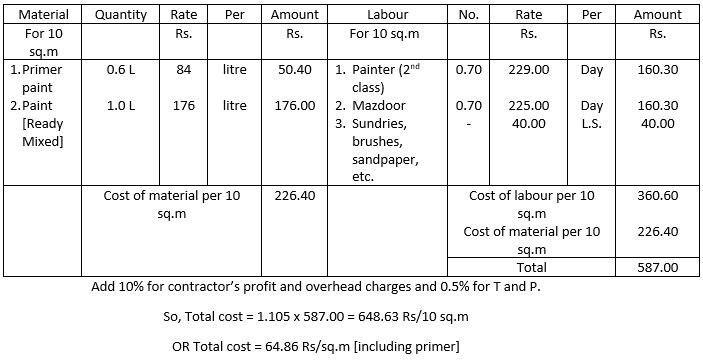

Painting two coats over a coat of priming for 10 sq.m area.

Providing water bound distemper of approved brand and shade in two coats [inclusive of priming coat of whitewash], scaffolding, etc. complete

Providing and fixing mangalore tiled roofing with class A-A tiles with horizontal teak wood battens, iron work and oiling the battens, etc. complete.

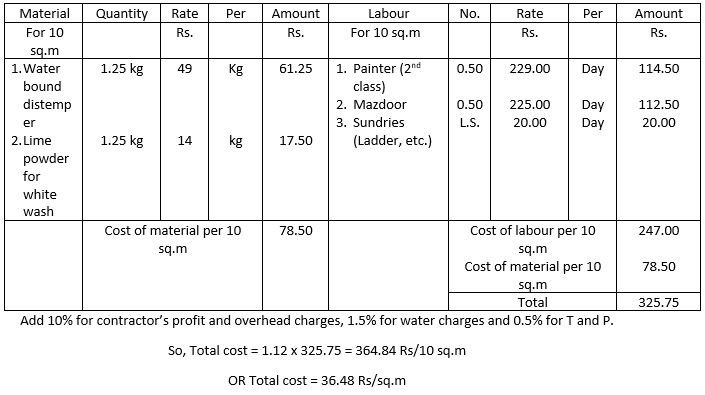

Providing flush grooved pointing with cement mortar (1:3) for brickwork including scaffolding and curing, etc. complete.

Providing 12 mm thick plastering in cement mortar (1:4) with neeru finish to internal surfaces including scaffolding, curing, etc. complete.

Providing 12 mm thick internal plastering in cement mortar (1:4) without neeru finish to concrete or brick surfaces including scaffolding and curing, etc. complete.

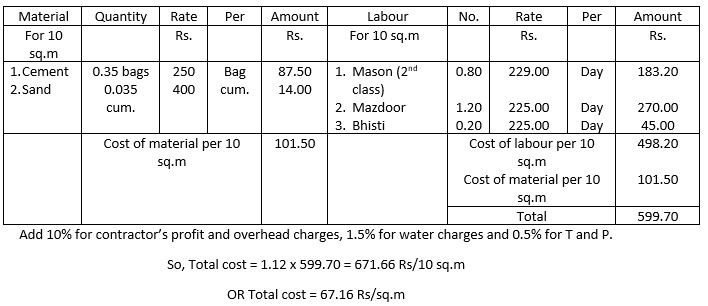

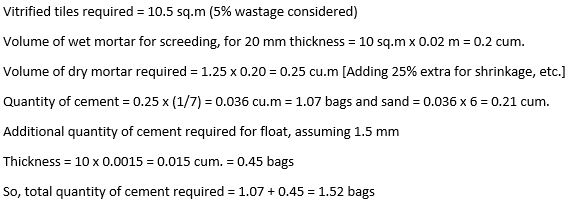

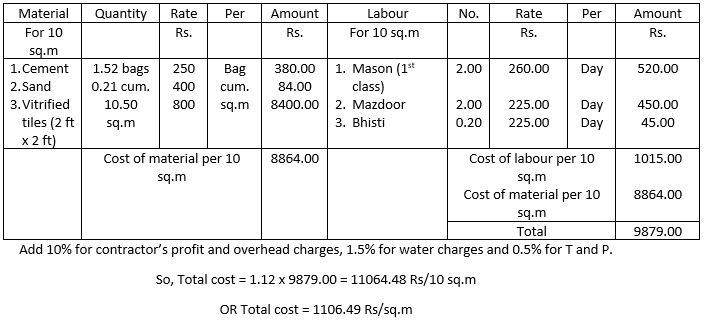

Providing and laying vitrified tiles, over 20 mm thick cement mortar (1:6) for 10 cum. area.

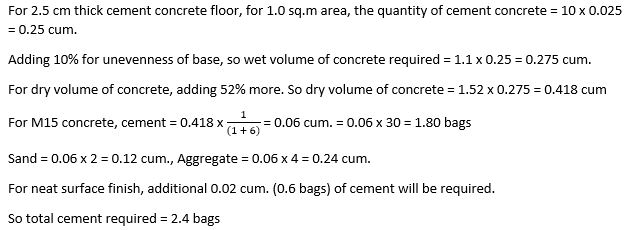

Providing and laying 2.50 cm thick cement concrete flooring using M15 (1:2:4) concrete for 10 sq.m area.

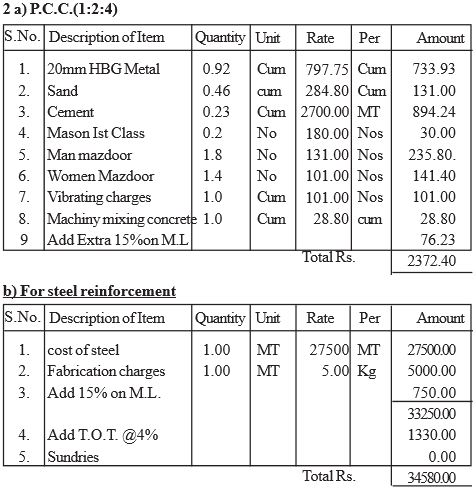

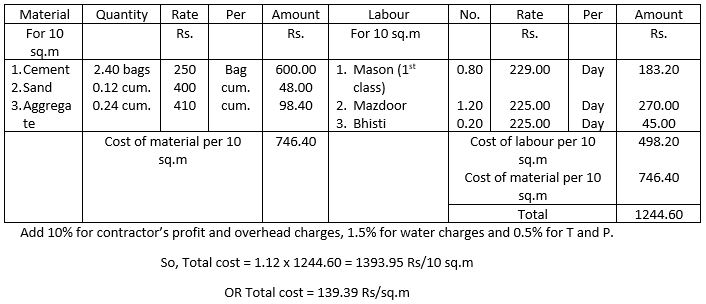

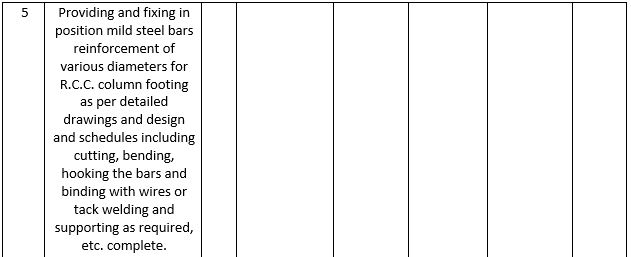

Providing and fixing in position mild steel reinforcement including bending, binding, hooking, wastage, laps, etc, complete.

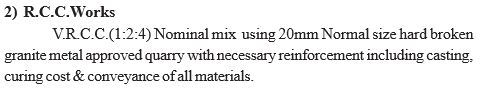

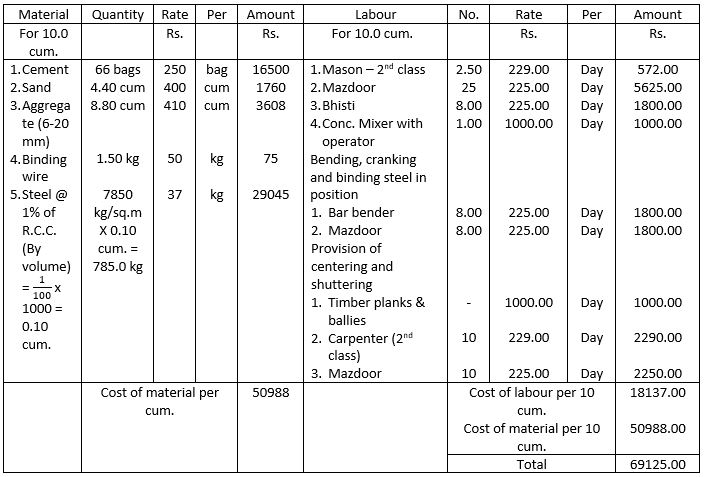

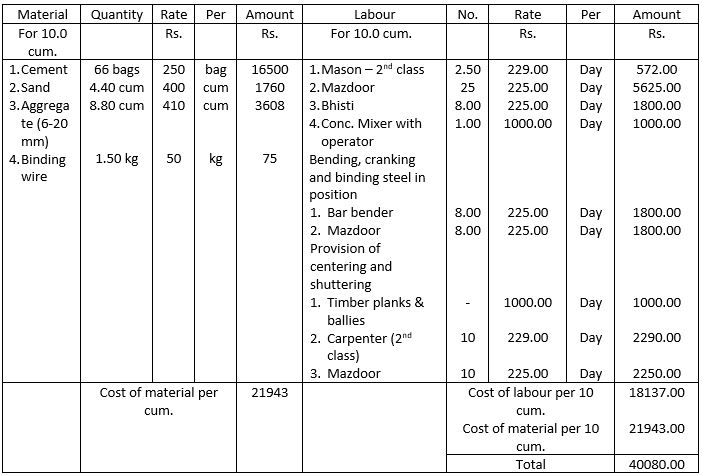

Providing cast in situ R.C.C. work in beams, slabs, etc. using M15 concrete (1:2:4) excluding steel but including centering, shuttering, bending and binding.

Providing cast in situ R.C.C. work in beams, slabs, etc. using M15 concrete (1:2:4) excluding steel but including centering, shuttering, bending and binding.

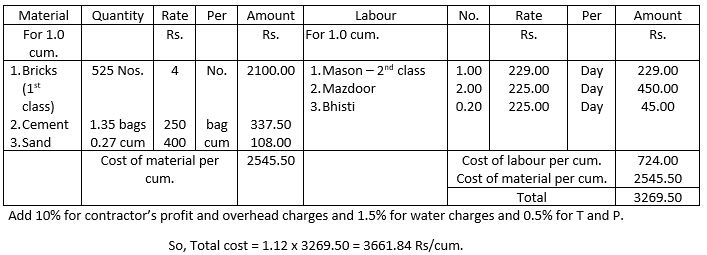

Providing 1st class brickwork in superstructure in cement mortar (1:6) with I.S. size bricks 19 cm x 9 cm x 9 cm including raking of joints, watering, scaffolding, etc. complete.

Providing and laying coursed rubble masonry in superstructure in cement mortar (1:6) including watering, scaffolding, etc. complete.

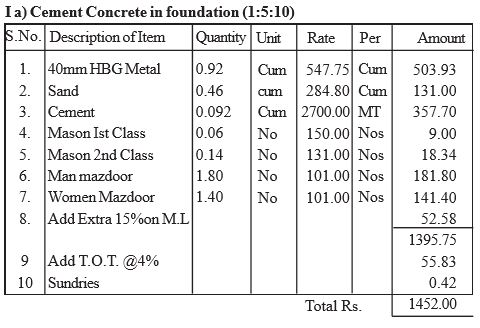

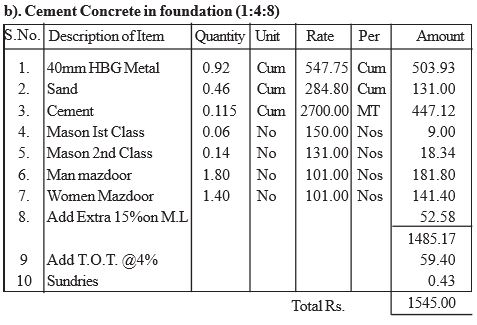

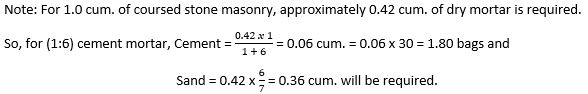

Providing and laying P.C.C. (1:4:8) in foundations including balling out of water manually, formwork, compaction, curing, etc. complete.

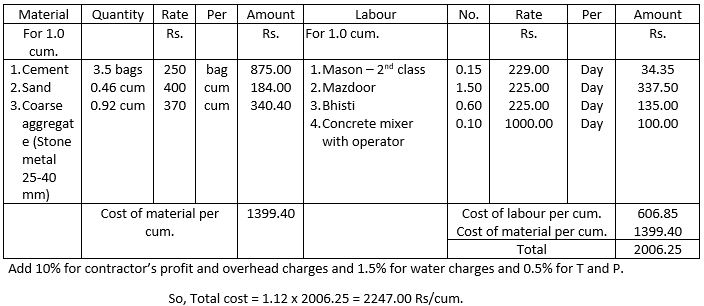

Providing and laying uncoursed (random) rubble masonry in cement mortar (1:6) including watering, scaffolding, etc. complete.

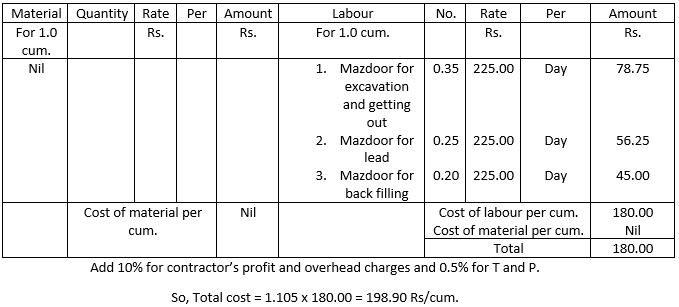

Excavation for foundation in earthen soil including removal of excavated material to normal lead of 50 m and lift of 1.5 m, shoring, strutting, preparing the bed for foundation, dewatering and back filling, etc. complete.

Unit 1 cum.

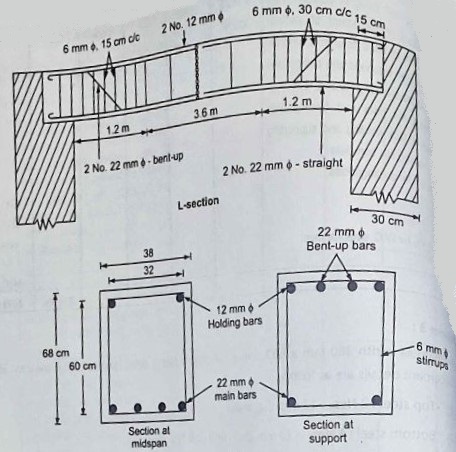

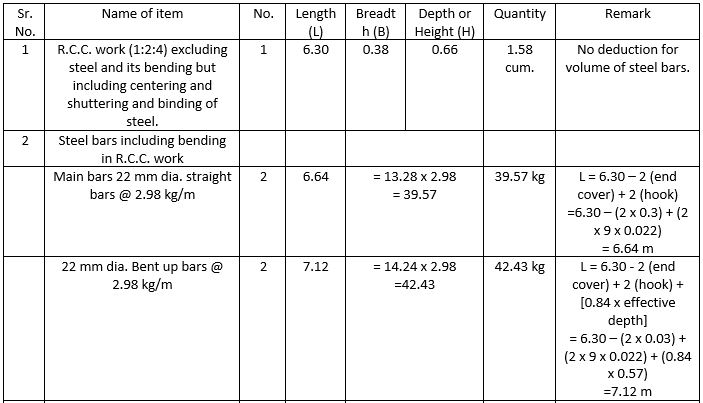

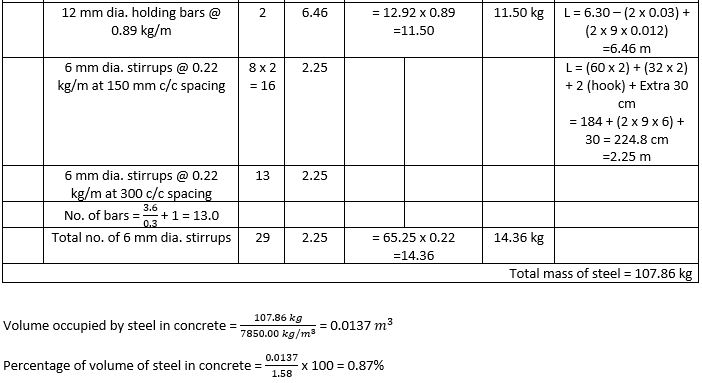

Estimation of R.C.C. Beam

Measurement Sheet

Abstract Sheet

To calculate the number of Mangalore tiles and battens required to cover an area of 10 sq.m

Size of Mangalore tiles = 41 cm x 24 cm

and it can cover an area of 32 cm x 21 cm

Therefore, Area covered by one tile with overlap = 32 cm x 21 cm = 0.32 sq.m x 0.21 sq.m

= 0.672 sq.m

Therefore, Total number of tiles required = (Area to be covered / Area of one tile with overlap)

= 10 / 0.0672 = 148.81 = 149 Nos.

Length of the ridge tile = 40 cm

The size of teak wood battens is equal to 5 cm x 2.5 cm and are usually fixed at 30 cm c/c

Therefore, the length of the battens required = 36 m

Item: Plain cement tiles 20 mm thick over cement mortar (1:6) screeding, including cement float, etc.

The quantities of plain cement tiles, cement and sand required for flooring 10 sq.m area will be determined as follows:

= 10 (sq.m) x 2 / 1000 (m) = 0.2 cum.

Quantity of Cement required for (1:6) proportion = 0.26 / (1+6) = 0.037 cum.

= 0.037 x 30 = 1.11 bags of cement

and Quantity of cement required for float, assuming 1.5 mm thickness = 10 x 0.0015

=0.015 cum.

=0.015 x 30 = 0.45 bags of cement

Therefore, Total quantity of cement required = 1.11 + 0.45 = 1.56 bags

and, Quantity of sand required = [0.26/(1+6)] x 6 = 0.222 cum. = 0.25 cum.

The volume of dry mortar required for pointing depends upon the type of surface i.e. either brick work or masonry work.

For pointing ( which may be flush, struck or keyed) to the brick work, the dry volume of mortar , including wastage, required for 10 sq.m area is about 0.036 cum. and for random rubble masonry it is 0.076 cum.

Thus knowing the proportion of the mix of the mortar as 1:3, the quantity of cement and sand can be found out as follows:

Volume of cement required = 0.036 / (1+4) = 0.009 cum.

= 0.009 x 30 = 0.270 bags

and, Volume of sand required = [0.036 / (1+3)] x 3 = 0.027 cum.

Therefore, For pointing in cement mortar (1:3) proportion,

Quantity of cement required = 0.076 / (1+3) = 0.019 cum.

= 0.019 x 30 = 0.57 bags = 0.60 bags of cement

and, Quantity of mortar required = [0.076 / (1+3)] x 3 = 0.057 cum.

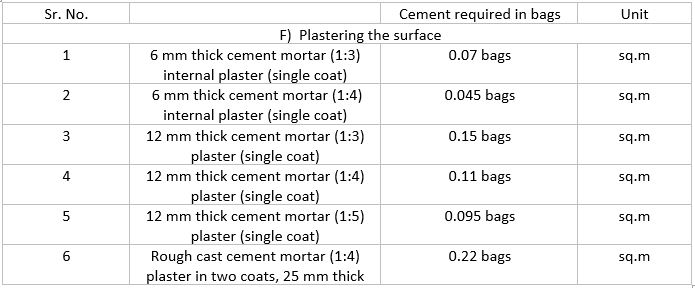

To determine the quantity of cement (or lime) and sand, required for plastering unit square metre of the area of various thickness is to work out the volume of mortar required per sq.m of plaster by multiplying the area to be plastered by its thickness.

In order to allow extra mortar for raked out joints, cavities, uneven surfaces, etc. the above worked out quantity is to be increased approximately by 30%.

Further to convert the wet volume of mortar into its corresponding dry volume, it should be increased by about 30%.

Then the quantities of cement and sand required can be determined by dividing the total dry volume of mortar by the sum of the numerical figures of proportion or mix of the mortar and multiplying it by the individual numerical figures.

e.g. To determine the quantities of cement and sand for 12 mm thick plaster in cement mortar (1:4), the procedure would be as follows:

Considering the area to be plastered as 10 sq.m, with a thickness of 12 mm, the quantity of wet mortar required = 10 (sq.m) x 1.2 / 100 (m) = 0.12 cum.

Therefore, Adding 30% extra for filling joints, and uneven surface, etc., quantity of wet mortar required = 0.12 + (0.3 x 0.12) = 0.156 cum.

Therefore, Quantity of dry mortar required = 0.156 + (0.3 x 0.156) = 0.156 + 0.0468

= 0.2028 cum.

Further, allowing for wastage, etc.

The total quantity of dry mortar required = 0.203 cum.

Therefore, Quantity of cement required = 0.203 / (1+4) = 0.041 cum.

= 0.042 x 30 = 1.23 bags

and Quantity of sand required = [0.203 / (1+4)] x 4 = 0.162 cum.

Approximate method

The approximate method of determining the volume of dry mortar required is to multiply the quantity of wet mortar required by a factor 1.8

i.e. Volume of wet mortar required = 0.12 cum.

Therefore, Volume of dry mortar required = 0.12 x 1.8 = 0.216 cum.

Therefore, Quantity of cement required = 0.216 / (1+4) = 0.043 cum.

= 0.043 x 30 = 1.29 = 1.30 bags

and, Quantity of sand required = [0.216 / (1+4)] x 4 = 0.0173 cum. which is same as determined above.

Neeru finish coat of 1.5 mm thickness.

If the inside face is to be plastered further with a Neeru finish of 1.5 mm thickness then the quantity of Neeru required for 10 sq.m surface

= 10 (sq.m) x 1.5 / 1000 (m)

= 0.015 cum.

i.e. 0.015 x 30 = 0.45 bags = 0.5 bags of Neeru which is available as ‘Sagol’ or ‘Sunala’ as brand name in the market.

In order to calculate the quantities of cement and sand required for 10 cm thick brick partition wall, with I.S. size (i.e. modular) bricks, the procedure would be as follows.

Considering 10 sq.m area of the brick work to be constructed with 10 cm thick wall.

The quantity of brick work in partition = 10 x (10/100) = 1 cum.

Therefore, Number of bricks required (considering the thickness of joints on 10 cm)

= 100/(0.20 x 0.1 x 0.1)

=500

Adding 5% extra for wastage = 25

Therefore, Total number of bricks = 525

Therefore, Quantity of mortar required = (10 x 0.1) – 500(0.19 x 0.9 x 0.9) = 1 – 0.77 = 0.23

Adding 10% extra for frog, bonding, wastage, etc. = 0.023

Therefore, Wet volume of mortar required = 0.253 cum.

Therefore, Dry volume required = 1.25 x 0.253 = 0.316 cum. = 0.30 cum.

i.e. for 10 sq.m area of brick work thickness 10 cm, the quantity of dry mortar required = 0.3 cum.

Further, knowing the proportion of mix, the quantities of cement and sand can be found out by dividing the total quantity of dry volume of mortar by the sum of the numerical figures of the proportion or mix of the mortar and then multiplying it by the individual numerals.

Therefore, Volume of one I.S. size brick, with thickness of joint as 1 cm = 0.20 x 0.1 x 0.1 = 0.002 cum.

Therefore, For 1 cum. of brick work, the total number of I.S. size (i.e. modular) bricks required = 1 cum. /0.002 = 500 Nos.

Therefore, Adding 5% towards wastage = 25

Therefore, Total number of I.S. bricks required = 525 Nos.

Now,

Quantity or volume of wet mortar required = (Total volume of brick work) – (Volume occupied by 500 bricks of 19 cm x 9 cm x 9 cm size)

= (1 – 500 x 0.19 x 0.09 x 0.09) cum

= 1 – 0.7695

=0.2305 cum.

In order to allow for mortar for filling the frog, bonding and wastage during its use, 10% is to be added.

Therefore, Volume of wet mortar required = 0.2305 + 0.10 x 0.2305

= 0.235 cum.

Therefore, Dry volume of mortar required = 1.25 x 0.235

= 0.316 = 0.30

i.e. Approximately for 1 cum. of brick work, 30% of the dry mortar will be required.

Calculations of materials for 1 cum. of brick work in C.M. (1:6) with traditional size bricks 9″ x 4.375″ x 2.75″ (i.e. 22.86 cm x 11.11 cm x 6.985 cm)

Assuming thickness of joint as 1 cm throughout, the nominal size of traditional bricks = 23.86 cm x 12.11 cm x 7.985 cm

Therefore, Volume of one traditional size brick with 1 cm as thickness of joint = (0.2386 x 0.1211 x 0.07985) cum. = 0.002307 cum.

Number of traditional bricks required for 1 cum. of brickwork = 1/0.002307

= 433 Nos.

Add 5% towards wastage = 22

Therefore, Total number of traditional bricks required = 455 Nos.

Now, Value of wet mortar required = 1 – 433 x (0.2286 x 0.1111 x 0.06985)

= 1 – 0.77

= 0.23 cum. which is practically same as derived above

Therefore, Adding 10% extra for wastage = 0.023 cum.

Therefore, Wet volume of mortar required = 0.253 cum.

Therefore, Dry volume required = 1.25 (wet volume)

= 1.25 x 0.253

=0.316 cum. = 0.30 cum.

i.e. approximately 30% of dry volume of mortar is required for constructing 1 cum. of brick work. Further, knowing the proportion of cement mortar the quantities of cement (in bags) and sand can be worked out as usual.

e.g. knowing the proportion of the cement mortar, the quantities of cement and sand required can be determined as follows.

For cement mortar (1:6) proportion,

Quantity of cement required = (Dry volume of mortar)/(1+6) = (0.316/7)

= 0.045 cum. = 0.045 x 30 = 1.35 bags of cement

and, Quantity of sand required = (0.316/7) x 6 = 0.2708 cum. = 0.27 cum.

Approximate method:

The above quantities can be determined by an approximate method as follows:

For 1 cum. of brick work divide 0.3 by the sum of the proportion of the material to obtain the quantity of cement in cubic metre

i.e. Quantity of cement required = (0.3)/(1+6) = 0.3/7 = 0.043 cum.

But as certain amount of cement will be required to fill the voids in the sand, add 0.002 cubic metre extra.

Therefore, Quantity of cement required = 0.043 + 0.002 = 0.045 cum. which is same as above

Therefore, Number of cement bags required = 0.045 x 30 = 11.35 bag

and, Quantity of sand required = 0.045 x 6 = 0.27 cum.

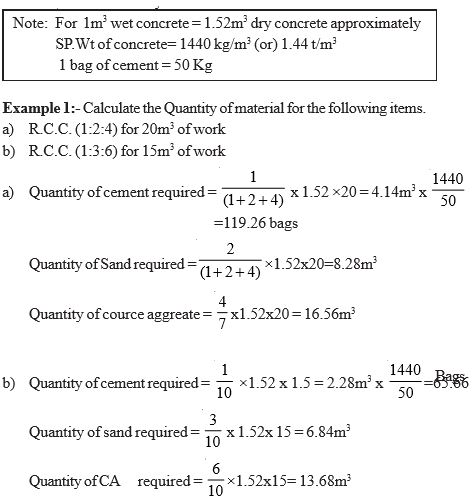

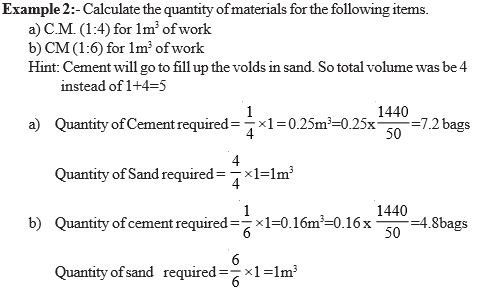

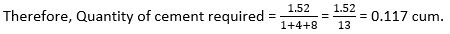

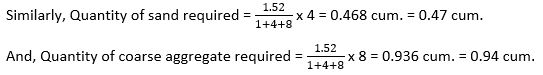

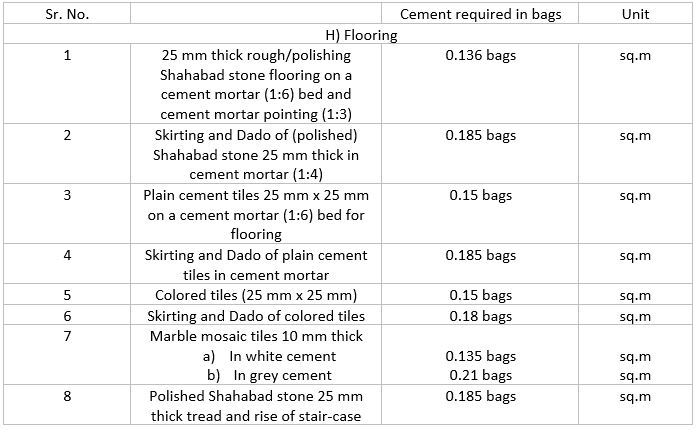

To determine the materials required for 1 cum. of (wet) concrete of 1:4:8 proportion, the dry volume of concrete required will be 1.52 cum. (which shrinks to 1 cum. after adding of water to it)

As 1 cum. of cement is equivalent to 30 bags of cement (each bag weighing 50 kg)

The quantity of cement required = 0.117 x 30 = 3.51 bags = 3.50 bags.

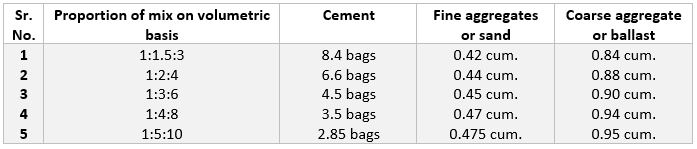

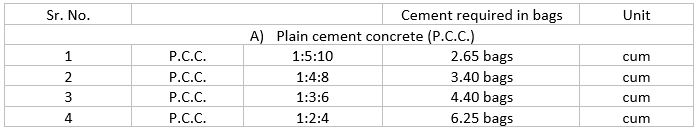

The following table gives the quantities of materials required for cement concrete of various proportion (i.e. mix) by volume.

Item of Work

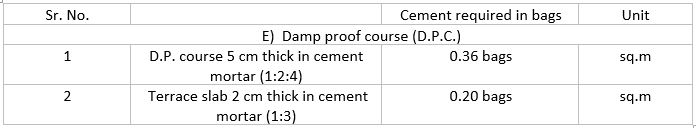

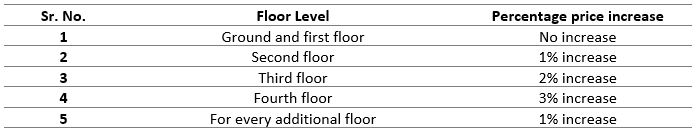

Note: For items of construction of superstructure of a building, the prices (i.e. rates) are to be increased for subsequent floor as more effort is required for transporting material to subsequent floors: The above increase in price shall be over the ground floor rates only.

The above increase in price shall be over the ground floor rates only.

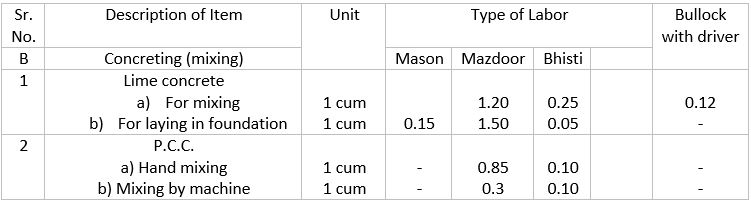

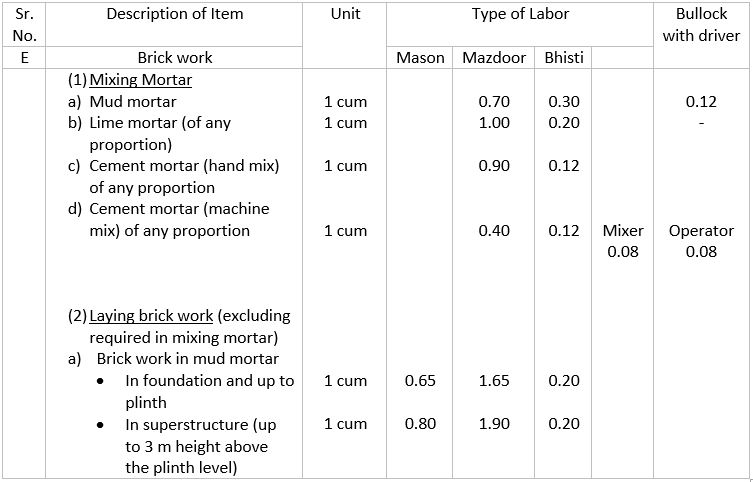

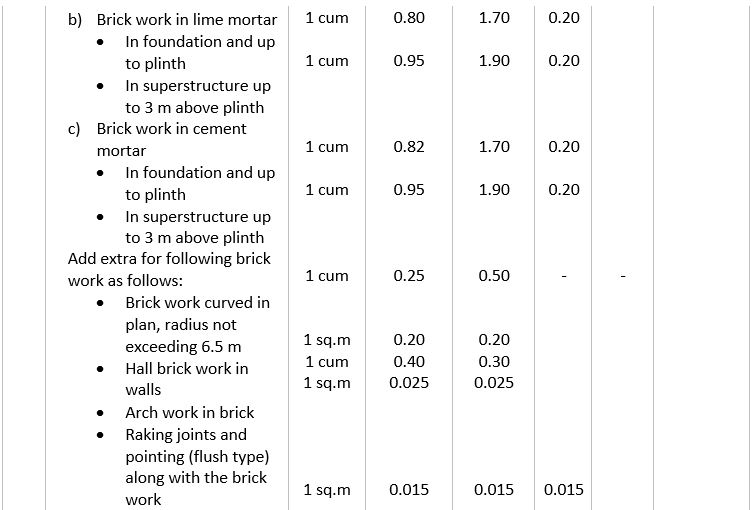

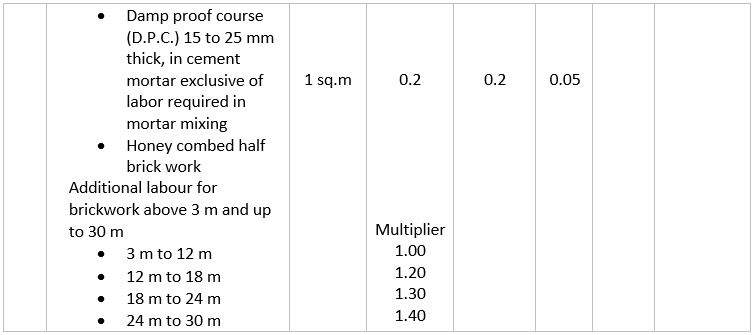

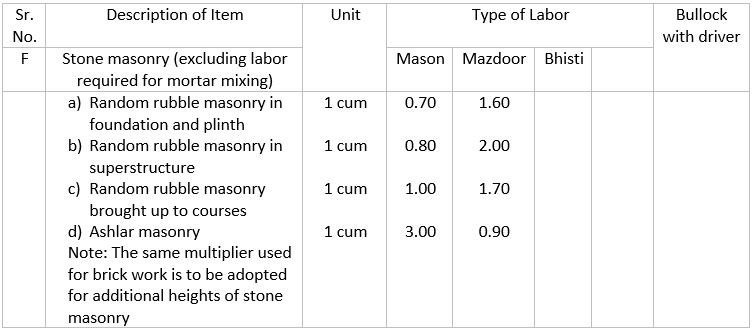

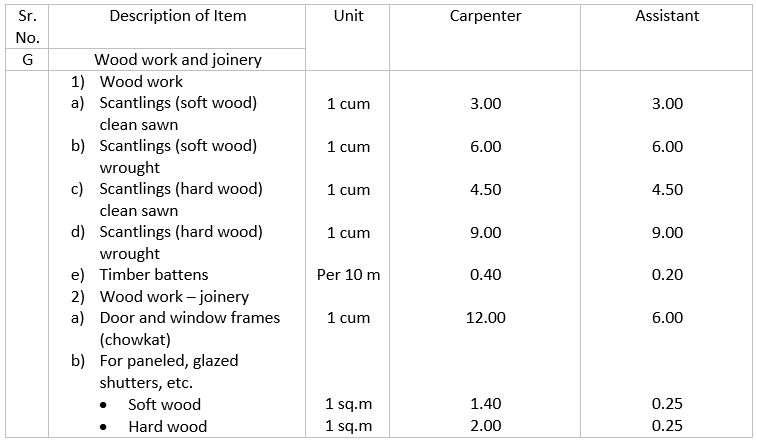

The Report of Productivity project of National Building Organization (N.B.O.) New Delhi specifies the labor requirements of various categories for different items of work as follows:

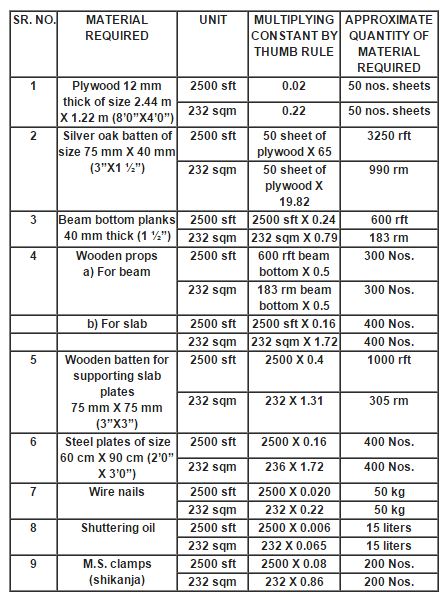

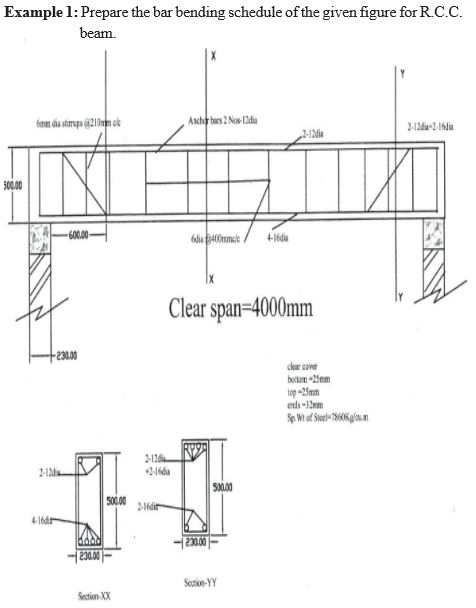

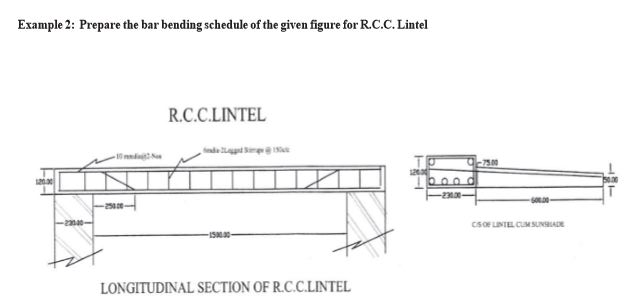

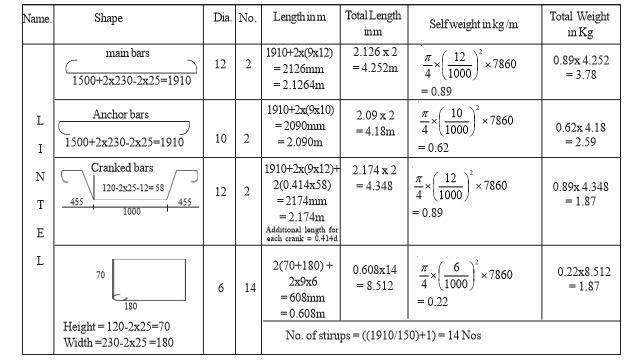

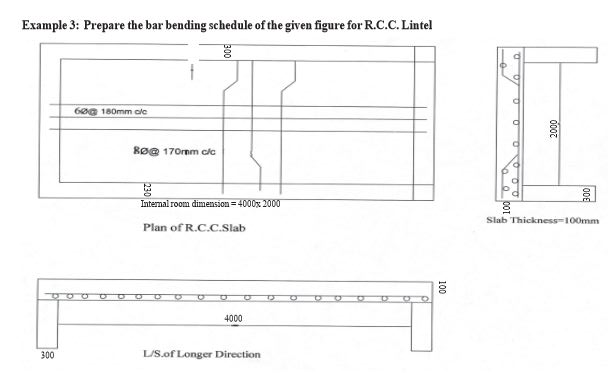

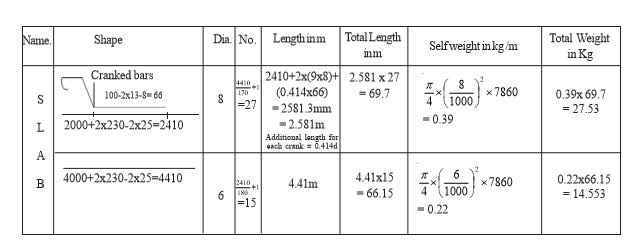

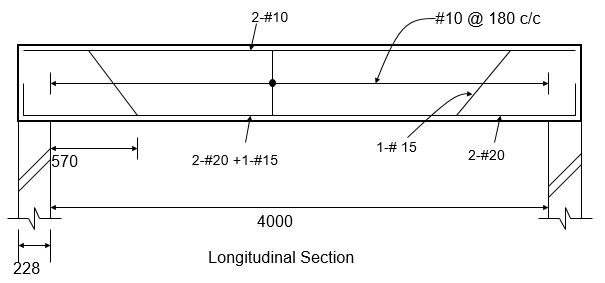

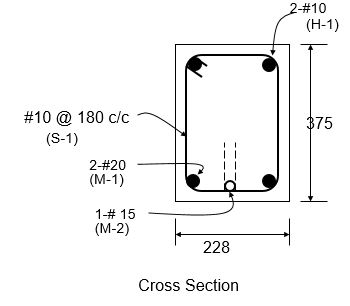

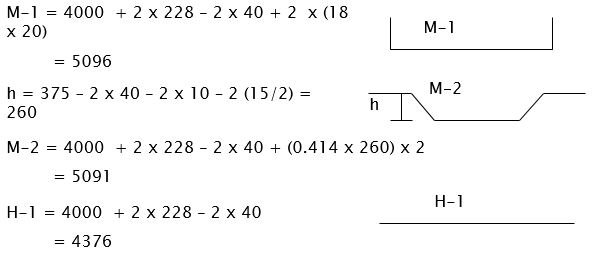

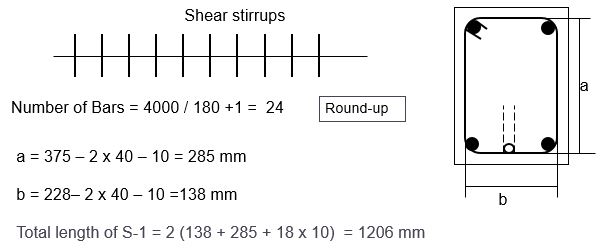

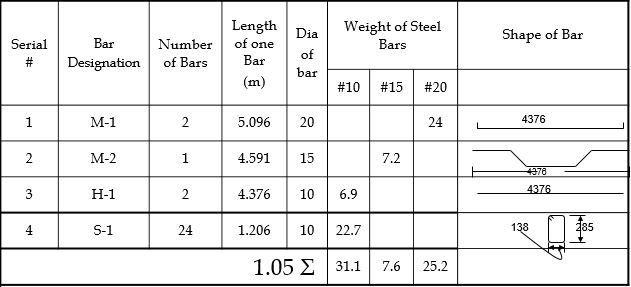

Example: Prepare bar bending schedule for the given beam. Clear cover = 40 mm

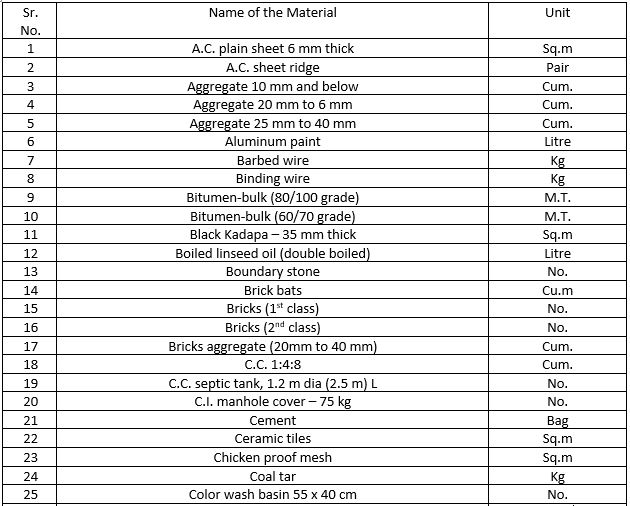

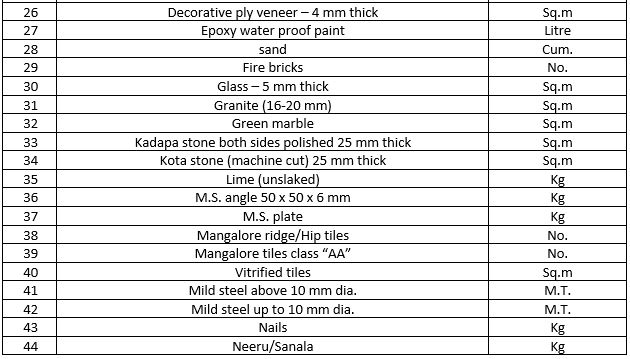

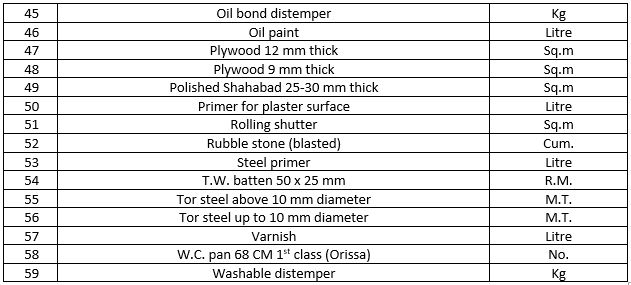

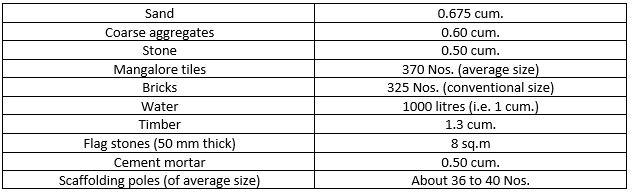

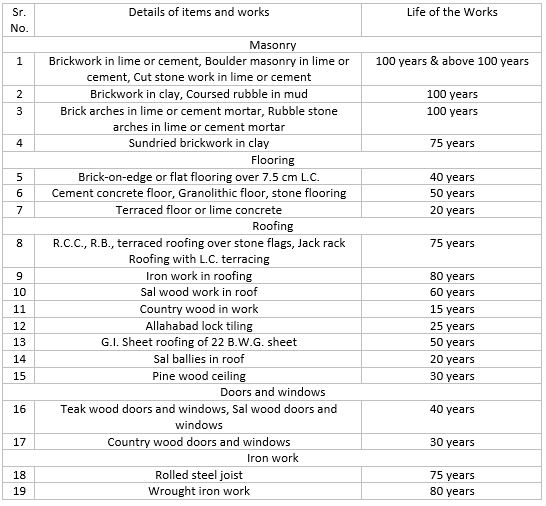

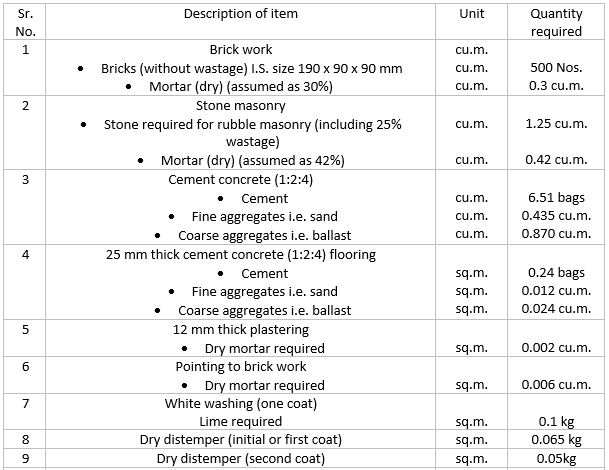

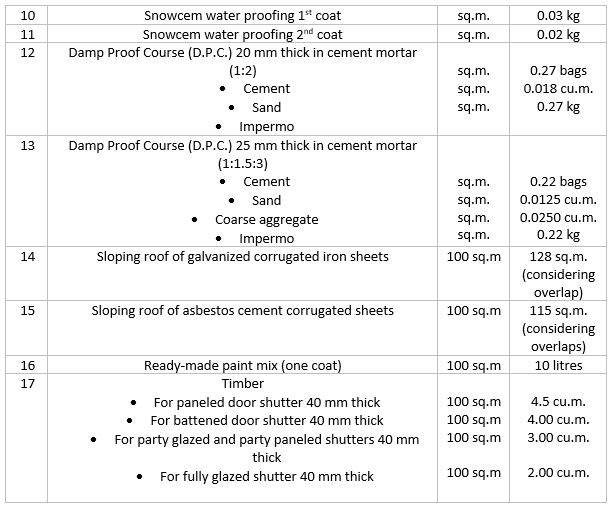

The table below shows the quantities of materials required for different items in construction:

The task work stated below is to be used as a guidance only and should not be quoted as a rule.

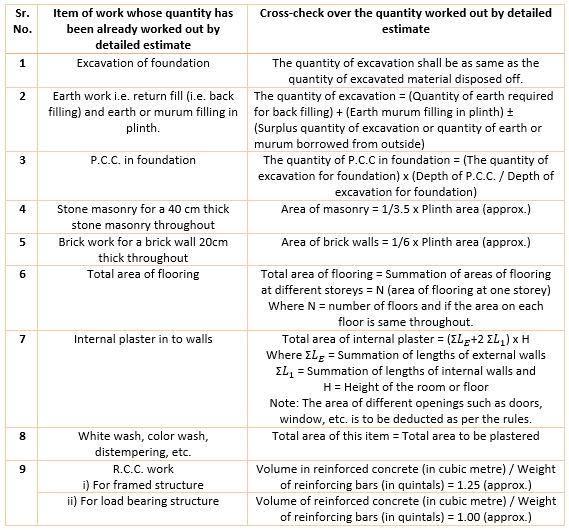

In order to ensure that the quantities of the various items worked out in a detailed estimate are fairly correct, it is necessary to apply cross-checks as specified:

(a) The units and methods of measurement for repair works shall generally be the same as those employed for the construction of the item of work.

Point wiring shall be classified according to the length of wiring as

|

Short points |

Not exceeding 3 m in length |

|

Medium points |

3 to 6 m in length |

|

Long points |

6 to 10 m in length |

|

Special Points |

Length exceeding 10m |

(a) The length of wiring from the main switch board to the sub-main board shall be considered as circuit wiring and shall be measured separately in running metre stating the type and size of wire.

(a) Service connection shall be fully described stating the type and size of the wire and shall be measured as follows

|

Insulated cables |

In running metre |

|

Bare cables |

In kg or quintal |

(b) All over-head bare wire or cables shall be measured in kg of the actual length fixed.

(c) Pole and struts for over-head links shall be enumerated and described stating the type, sectional size, girth or diameter and the total length.

(d) Steel brackets, cross-arms, clamps, etc., fixed to poles and struts shall be fully described and enumerated under separate item.

(e) Stay assemblies shall be enumerated and fully described including excavation, concrete, etc.

(f) Earthing poles and service connections shall be enumerated and fully described as including earth electrode, packing charcoal, earth wire, etc.

(a) Gullies, syphons, intercepting traps, etc., including concrete bedding and setting in position shall be enumerated stating the size.

(b) Connection of fittings, elbows, bends, tees, connectors, unions, diminishing sockets and the like shall be enumerated.

(c) Cutting through walls, floors, etc., and making good shall be included with the item.

(d) Closet pans, urinals, flushing cisterns, lavatory basins, bath tubs, shower rose and other fittings shall be enumerated stating the size and fully described.

(e) Sluice valves, stop cocks, hydrants, surface boxes, water meters, etc., shall be described stating size and enumerated.

(f) Bib-cocks, pillar cocks, ball cocks, ferrules, grating, etc., shall be described stating the size and enumerated.

(g) Boilers, cisterns, cylinders, water tanks, etc., shall be enumerated stating the size, capacity, materials, etc., and fully described.

(a) Manholes up to 6m depth shall be enumerated stating the size and depth and shall include cast iron cover with frame (weight to be stated), foot iron, inverts, materials and mortar, framework, etc., all of which shall be fully described.

(b) Manholes shall be classified under three different groups as follows: –

|

Shallow |

Up to 2.1m in depth |

|

Deep |

Above 2.1m and up to 4.2m in depth |

| Extra Deep |

Above 4.2m and up to 6.0m in depth |

(c) Manholes under each classification shall be enumerated separately stating the size and least depth and the extra depth shall be measured in running metre and totaled up separately for each classification and taken as ‘extra over’ under separate item following the main item.

(d) Depth shall be from the top of manhole to the invert of channel.

(e) Manholes exceeding 6 m in depth shall be measured in details under the various items of works, brickworks, concrete, C.I. cover with frame, etc.

(a) Painting of door and window shall be measured closed and flat, not girthed in sq.m. and shall include chaukhats, edges, cleats, etc.

(b) Different types of doors and windows as battened, paneled, glazed, etc., shall be grouped under one item and the areas of uneven surfaces shall be covered into equivalent plain area by multiplying the flat measured area by a multiplying factor.

(c) The coefficients or multiplying factors for different surfaces to get equivalent plain area are as given below: –

|

Particulars |

Method of Measurement |

Multiplying Factor |

|

Doors and windows |

||

| 1. Paneled, framed, and braced, ledged and battened, ledged battened and braced. | Measured flat not girthed including chaukhats, edges chocks, cleats, etc., shall be included in the item. | 1 1/8 (for each side) |

| 2. Fully glazed or gauged | Same as above | ½ (for each side) |

| 3. Part paneled and part glazed or gauged | Same as above | 1 (for each side) |

| 4. Flush door | Same as above | 1 (for each side) |

| 5. Flush venetioned or louvered | Same as above | 1 ½ (for each side) |

|

Miscellaneous works |

||

| 6. Boarding with cover fillets and match boarding | Measured flat not girthed | 1 1/20 (for each side) |

| 7. Roof battens (tile or slate roof) | Measured flat overall, no deduction for open spaces | ¾ (for painting all over) |

| 8. Trallies or jaffri work one way or two way | Same as for (6) above. (Supporting members shall not be measured separately) | 2 (for painting all over) |

| 9. Guard bars, balustrates, grating, railings, grills, expanded metals, etc. | Measured flat overall no deduction for open spaces | 1 (for painting all over) |

| 10. Corrugated iron sheeting in roof | Measured flat not girthed | 1.14 (for each side) |

| 11. A.C. corrugated sheeting in roof | Measured flat not girthed | 1.20 (for each side) |

| 12. A.C. semi corrugated sheeting in roof | Measured flat not girthed | 1.10 (for each side) |

| 13. Steel rolling shutters | Measured flat not girthed | 1 ¼ (for each side) |

| Corrugated iron sheet | 14% |

| Corrugated asbestos cement sheet with large corrugations (as Big six sheets) | 20% |

| Semi – corrugated asbestos cement sheets (as Trafford sheets) | 10% |

(a) Structural steel works as girders, compound girders, plate and lattice girders, steel stanchions, trusses, framed steel work, etc., shall each be taken under separate item and measured in quintal and fully described.

(b) No deduction shall be made for rivet and bolt holes.

(c) In riveted work, the weight of rivet heads, except in case of countersunk rivets, shall be added.

(d) The weights of cleats, brackets, packing pieces, separators, gusset and fish plates, bolts and nuts, rivet heads, etc., shall be added to the weight of the respective items.

(e) The work shall include fabrication, hoisting, placing, fixing in position.

(f) Site drilling to existing steel work shall be enumerated stating the diameter of bolts and thickness of metal.

(g) Rivets driven at site shall be enumerated as ‘extra over’.

(a) Bolts, holding down bolts, anchor bolts, etc. shall be measured in quintal separately including nuts and head, and washers shall be grouped according to the diameter.

(b) Grills grating, framed guard bars, ladders, brackets, etc., shall be measured in quintals separately and shall be fully described.

(c) If specified grills, grating, etc., may be taken in sq.m. and fully described.

(d) Iron hold fasts shall be taken by weight in quintal, or enumerated stating the length, breadth and thickness of flat iron.

(e) The method of fixing with bolt of screw and embedding in cement concrete or cement mortar shall be described and included in the item.

(f) Flue pipes shall be measured in running metre stating the diameter and the type of pipe, gauge or weight per unit length and method of jointing and fixing shall be described.

(g) Cast iron balusters and newels shall be enumerated and fully described including the methods of fixing.

(h) Cast iron railings shall be measured in running metre stating the height and fully described including the method of fixing.

(a) Cast iron spiral staircase shall be enumerated (i.e., counted as one for complete work) stating the overall diameter, total number of treads and total height above ground level.

(b) The description shall include tread, riser and sleeves in one piece, including hand rails, balusters, etc.

(c) Cast iron chequered plates shall be described and measured in quintal.

(d) Expanded metal, wire netting, etc., shall be measured in sq.m. stating gauge and mesh.

(e) No deduction shall be made for opening up to 0.2 sq.m.

(f) Different items shall be kept separate.

(a) Bar reinforcement shall be measured by weight in quintal stating the diameter and shall include cutting to length, hooked ends, cranking or bending, etc.

(b) Authorized overlaps shall be measured.

(c) Different diameter bars shall be kept separate.

(d) Binding wire shall not be measured separately, this shall be included in the item.

(e) Fabric reinforcement shall be taken in sq.m. stating the mesh and size of standard.

(f) Wire netting in wrappings to steel work embedded in concrete or plaster, in encasing steel work shall be measured separately in sq.m. stating the mesh and gauge.

(g) Hoop iron shall be measured in running metre stating the width and gauge.

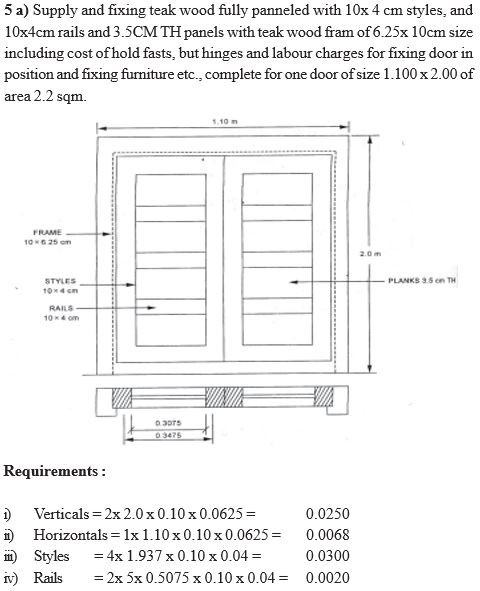

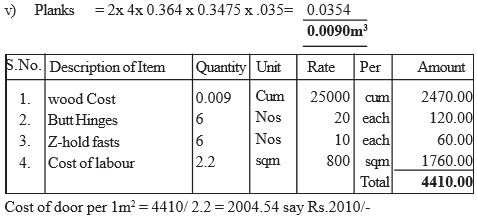

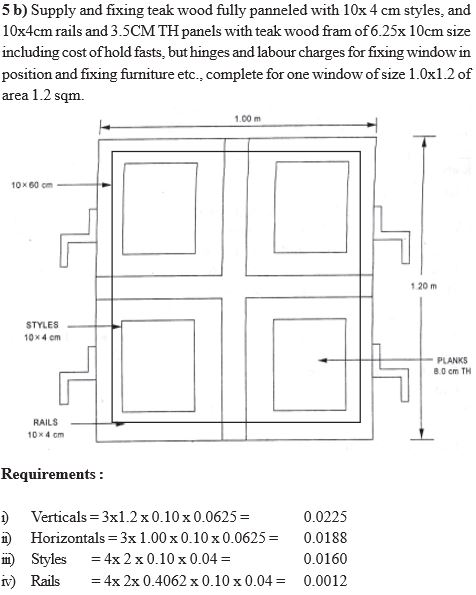

(a) Generally, all woodwork of which the scantling exceeds 20 sq.cm. in section and which is not specially molded or carved comes under carpenter’s work.

(b) This includes all timber work in door and window chaukhats, in roof works as beams, struts, ties, rafters, purlins, (all work in roof trusses), in timber bridge, in verandah posts, in centering and shuttering, in shoring and the like.

(a) Woodwork which is prepared, turned, molded, carved and jointed together comes under joinery.

(b) Joiner’s work requires finishing and putting together at the bench and includes door and window shutters, framed partitions, furniture and the like.

Carpenter’s work

(a) Roof boarding, ceiling, floor, shelves, partitions, etc., shall be taken in sq.m. stating the finished thickness and shall be fully described.

(b) Supporting beams, frame work, shall be taken separately in cu.m.

(a) Normally, centering and shuttering (formwork) shall not be measured separately but included in the rate of C.C. or R.C.C. work.

(b) If specified that the formwork shall be paid separately, the formwork shall be measured as the actual surface contact with the concrete and taken in sq.m. and shall include planking, beams, props, wedges, nails, etc.

(c) Formwork of different kind of works as beams, lintels, floors, roofs, walls, columns, staircases, etc., shall be measured under separate items and fully described.

(d) For slabs, chujjas, arches, shells and domes only the area of bottom shuttering in contact with concrete surface shall be measured and side shuttering shall not be taken into account.

(a) Roof battens, where not included with the item of roof, shall be taken as surface area of the roof in sq.m. stating the size of battens and the spacing.

(a) Fillets, beadings, etc., shall be measured in running meter stating the width and thickness.

(a) Finishing of fillet as edge chamfered, rounded or molded shall be described.

(a) Ballies shall be measured in running meter stating the mean diameter which shall be average of the two diameters at the ends.

(a) Wood piles shall be measured in running meter stating the size.

(b) Steel shoes and heads of piles shall be enumerated separately stating their weights.

Joinery

(a) Shutter shall be taken in sq.m. stating the thickness and the kind of wood and both faces shall be described.

(b) Measurement shall be taken from inside after closing the shutters excluding chaukhats.

(c) Different types of shutters are:

(d) Ledged and battened,

(e) Ledged, braced and battened,

(f) Framed, ledged braced and battened,

(g) Framed and paneled,

(h) Framed and louvered,

(i) Flush,

(j) Glazed,

(k) Part paneled and part glazed, etc., shall be taken separately and each type fully described.

(a) For supply, glass panes shall be measured in sq.m. stating the thickness and type of glass.

(b) Measurement, length and breadth, shall be taken to the nearest 5 mm.

(c) Irregular or circular panes shall be measured at the smallest rectangular area from which they can be cut unless otherwise specified.

(a) Chaukhats, mullion and transoms shall be taken in cu.m. and the length of tenon, horns, etc., shall be added to the sight lengths.

(b) The sectional area shall be the area of the least square and rectangle from which they may be cut or made.

(c) Rebates, beads, chambers, etc., shall be described and included with the item.

(d) Portion of chaukhats of segmental or circular shape shall be measured separately and described.

(e) Type of wood shall be stated and chaukhats of different kind of wood shall be kept separate.

(a) Work of staircase shall be measured under separate heading.

(b) Landing including bearers shall be measured under a separate item in sq.m. of the upper surface, stating the thickness.

(c) Treads and risers shall be taken in sq.m. stating thickness, the area being obtained by multiplying the length of tread by the exposed width of the tread plus the rise from step to step and the work shall be described stating the kind of timber’s method of jointing, fixing, etc.

(d) Hand rails shall be taken in running meter and measured along the top centre line stating the extreme section of the straight portions and molding and rounding.

(e) Balusters shall be taken in numbers stating the size and shall include framing, at ends shall be fully described.

(f) Newels shall be described and measured in running meters stating the section and nature of finishing.

(a) Towel rails, contain brackets, plate racks, toilet fixtures, small fittings, furniture, etc., shall be taken in numbers stating the size and shall be fully described.

(a) Builder’s hardware is the trade name of the articles made of base metal as iron, steel, copper, etc.

(b) The various kinds of builder’s hardware shall be described and enumerated and taken separately according to the materials, finish, size and pattern.

(c) The following articles comes under builder’s hardware: –

-Hinges, door handles, hasp and staples, locks, hat pegs, hat and coat hooks, wardrobe hooks, knobs, springs, screwed eyes, cleats, latches, bolts and the like.

-Curtain rods or poles, curtain rails, rails for running sashes, etc., shall be measured in running meter stating diameter and size.

(a) Glazing shall be measured in sq.m. stating the quality, weight and thickness.

(b) The method of glazing and fixing with putty, wooden beads, metal beads, etc., shall be fully described.

(c) Different kind of glass and different methods of fixing each shall be taken separately.

The stone masonry in uncoursed rubble or coursed rubble, etc. shall be measured separately in cubic metres. Usually stone masonry in foundation and up to plinth (if of the same type) is included under one item and the masonry in superstructure is considered as separate item. For multi-storeyed buildings, the masonry at each floors is to be measured separately.

The procedure of calculating the net quantity of stone masonry is to assume all walls as solid and to calculate its cubic contents, and then deductions are to be made for the various openings such as doors, windows, ventilators, etc.

The rules of deduction for the openings in stone masonry are same as for openings in the brick work already explained in the topic ‘Brick Work’

The stone work for sill and parapet copings are measured in running meters, specifying the item fully in the description column.

The face stone work for weather sheds, shelves, slabs, etc. are measured in square metre.

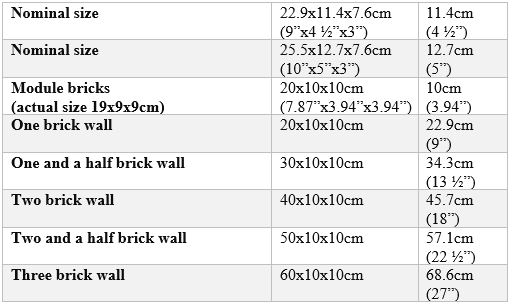

(a) Brick walls up to and including three bricks in thickness shall be measured in multiples of half brick, which shall be deemed to be inclusive of the mortar joint.

(b) The following shall be taken as half brick measurement: –

(c) For walls which are more than three brick in thickness, the actual thickness shall be measured to the nearest 1 cm (½”).

(d) Where fractions of half brick occur due to architectural or other reasons, the measurements shall be taken as follows: –

-For fractions of 2 cm under actual measurement.

-For fraction exceeding 2 cm – full half brick.

(a) No deduction or addition shall be made for the following: –

-Opening up to 0.1 sq.m. in section.

-Ends of joints, beams, lintels, posts, rafters, purlins, corbels, steps, etc.

-Wall plates and bed plates, bearing of slabs, chujjas and the like where the thickness does not exceed 10 cm and the bearing does not extend over the full width (thickness) of wall.

The size of the bricks, its type, thickness of the joints, bond, etc., and the proportion of mortar shall be specified in the description of the item.

The main brick work is measured in cubic metres, and brick work in partition i.e., one brick thickness is measured in square meter specifying its thickness. Brick masonry in foundation and up to plinth is included under one item and the brickwork in superstructure is measured separately. In case of multi-storeyed building, the brick work of each floor is to be measured separately as the rates of the item go on increasing from ground floor to subsequent higher floors.

The general procedure of calculating the quantities of brick work in superstructure is to assume all walls as solid and find out its cubic contents, and then allow for the deductions for openings into it. Example: doors, windows, ventilators, lintels, etc. Different types of brick work with different proportion of mortar, etc. shall be measured separately.

Honey combed brick work is measured separately, specifying the thickness in square metres, no deductions being made for the holes in it.

Rules for deductions to be made for openings in brick wall are as follows:

Thus the quantity of deduction to be made shall be equal to:

(l + 2t) x (Thickness of lintel) x (Wall thickness)

where t = Thickness of lintel and l = Length of the opening.

It may be noted that lintels also from separate item to be measured in cubic metres. the quantity being equal to = (l + 2t) x t x Wall thickness

Brick work in columns and pillars shall be described fully and shall be measured separately in cubic metres.

Circular brick work above 6 m radius shall be measured in the general item of brick work in cubic metres.

Brick work in staircase, arches, etc. shall be measured separately in cubic metres.

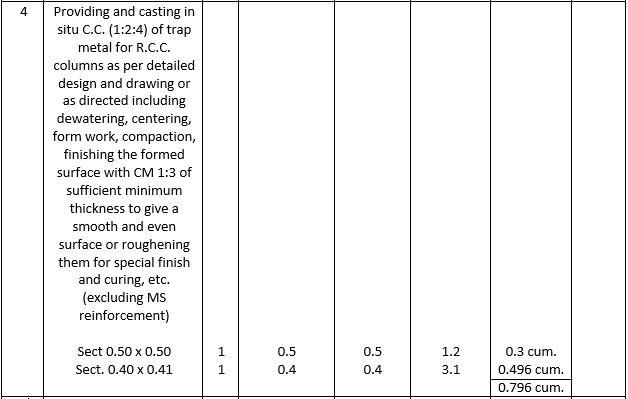

(a) Reinforced cement concrete shall be kept separate from unreinforced concrete,

(b) C.C. work shall be taken in cu.m. excluding steel, and the steel reinforcement shall be measured under a separate item in quintal (cwt), authorized overlap hooks, cranks, etc. of bars shall be measured.

(c) Normally, centering and shuttering (formwork) shall not be measured separately but included in the rate of R.C.C. or C.C. work.

(d) Binding wire is not measured separately.

(e) The volume occupied by reinforcement shall not be deducted from the measured concrete volume.

(f) The item of R.C.C. work shall include R.C.C. slabs, beams, lintels, columns, chujjas, staircases, foundation, rafts and footings, etc. and each of them shall be classified under a separate item.

(g) The exposed surface shall be fair finished which shall not be measured separately.

(h) Chujjas may be measured in running meter stating the projection and its average thickness, if specified.

(i) Special light weight partitions shall be measured in sq.m. stating thickness and fully described.

Precast C.C. reinforced or plain shall be taken separately in cu.m. and shall be described as including all molds, finished faces hoisting and setting in position.

Reinforcement, if any, shall be described and included in the item, or measured separate if specified.

(a) Expansion joints in roofs, floors, walls, road, etc. shall be measured in running meter.

(b) The depth and width of joint, and materials used for filling shall be described.

(a) Jallies or Jafferies, louvers shall be described and thickness specified and taken in sq.m.

(b) Reinforcement shall be described and included in the item.

(a) Fencing posts, corner posts, struts, etc., shall be taken in cu.m. and reinforcement and formwork shall be included and described.

(a) Concrete piles shall be described and taken in cu.m. and classified according to the section and length.

(b) Steel reinforcement shall be included with the item and fully described.

(c) Heads and shoes of steel or iron shall be enumerated i.e., taken in numbers and weight of each stated.

(d) Pitching and driving of piles shall be enumerated stating size and length.

If specified, the driving of piles may be taken and measured in running metre for the portion driven below ground level.

(a) Damp proof course shall be fully described and taken in sq.m. stating the thickness.

(b) The item shall include formwork, finishing, levelling, curing, etc.

(c) The horizontal and vertical damp proof courses shall be measured separately.

It may be plain cement or reinforced cement concrete:

(a) Plain Cement Concrete (P.C.C.):

(b) Reinforced Cement Concrete (R.C.C.):

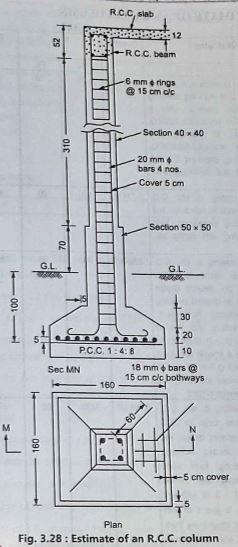

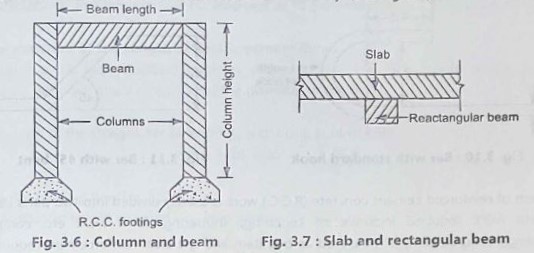

i) Columns: The length or height of the column shall be measured from top of the footing on which column rests to the underside of the first slab for the ground floor and the top of the floor slab to the underside of the floor slab immediately above it. (see Fig. 3.6)

ii) Beams: The length of the beam shall be measured clearly between the two columns and shall be inclusive of haunches between columns and beams, if any. (See Fig. 3.7)

The depth of the ordinary beam shall be measured from the bottom of the beam to the bottom of the slab above it. In case of inverted beams, however, it is measured from top of the slab to the bottom of the beam.

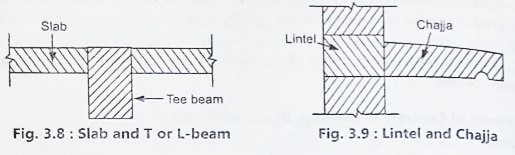

iii) Slab: The depth of the slab shall be measured from the top of the slab to the top of the rectangular beam lying below it. (See Fig 3.7) In case of slab and T or L-beam, the common portion shall be measured in the T-beam.

iv) In case of concrete chajjas combined with lintels or beam, the common portion shall be included into lintel only. (See Fig. 3.9)

The common portion at the junction of two similar members is usually included with only one item.

Example: In case of junction of column and beam, the common portion of the work is included in the column (See Fig. 3.6), and in case of slab and rectangular beam, the common portion is included in the slab (See Fig. 3.7), whereas in case of slab and T-beams (or L-beams), the common portion is to be included in the T (or L) beam. (See Fig. 3.8) and in case of lintel and chajja the portion common to it is measured in the lintel. (See Fig. 3.9

The item of reinforced cement concrete (R.C.C.) work is usually divided into two parts i.e., the concrete work required inclusive of centering, shuttering, form work, etc. completely (excluding reinforcement) is measured as one item and the steel reinforcement required is considered as another separate item, no deductions being made for the space occupied by the steel from the volume of concrete. Binding wire required is to be included in this item and separate measurements are required for it.

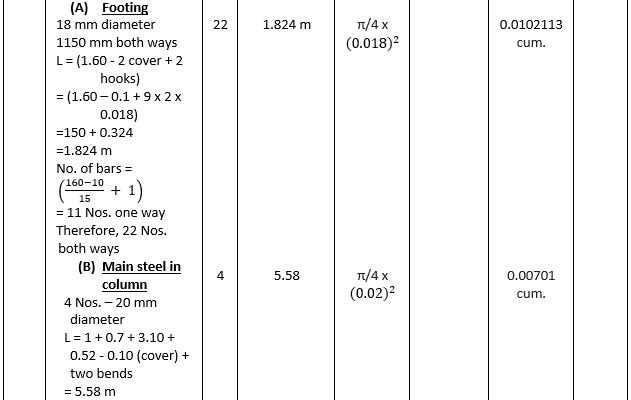

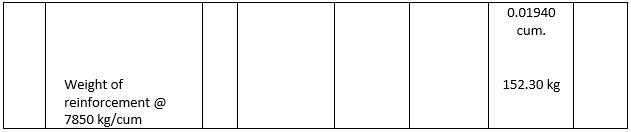

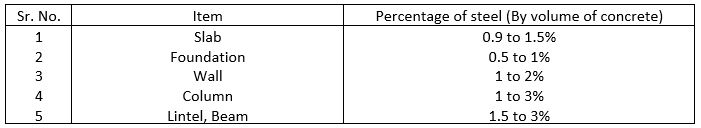

The quantity of concrete work in R.C.C. is calculated in cubic metres knowing the length, width, and depth of the concrete. The quantity of reinforcement steel to be laid in position is also worked out from the details shown on the drawings, making due allowance for overlaps, hooks and cranks, etc. In the absence of such detailed reinforcement drawings, the quantity of reinforcement steel may be worked out approximately on the percentage of the volume of concrete as specified below:

For foundation footings = About 0.5% of volume of concrete

For column = About 1.2 to 2.5% of volume of concrete

For beam = About 1 to 1.5% of volume of concrete

For slab and lintels = About 0.8 to 0.9% of volume of concrete

A thin rich cement plaster may be applied to the exposed R.C.C. surfaces to give uniform smooth finished surface, without making separate item. No deduction shall be made for the volume of the reinforcing bar from the volume of concrete.

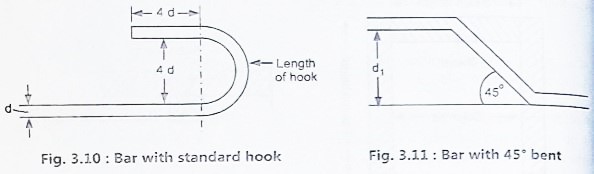

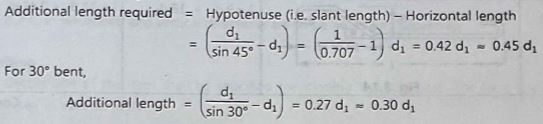

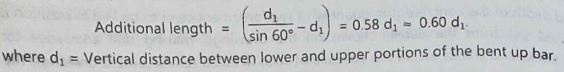

Consider a bar with standard hook as shown in Fig. 3.10. The length of the hook = d + 4d+ 4d = 9d, where d represents the diameter of the bar.

Length of the straight bar of length L, with hook at both ends = L + 9d +9d = L + 18d

For a 45 degree bent up bar (Fig. 3.11),

For 60 degree bent,

It is usual practice to prepare a schedule of reinforcement bars which will be useful for bar bender and supervisors, etc. It contains of a list of reinforcement bars specified in a tabular form, indicating its diameter, shape of bending with neat sketches, length of each angle of bent, its total weight, etc. Such a schedule of bars is prepared separately for each type of R.C.C. work such as slabs, beams, columns, etc. From the schedule of bars, it is possible to determine the total requirement of reinforcement for that item of work with its length, diameter, etc. and accordingly the job of bending of bars, etc. as per the drawings can be carried out before it is placed in the position before casting of the member.

Some of the usual types of reinforcement bars with the length of hooks and the total length of the bar required are as mentioned below:

(a) The measurement shall be taken separately for every 30 m lead or distance and every 1.5 m lift or height or depth.

(b) The lead shall be measured from the centre of the area of excavation to the centre of the area of spoil heap.

(c) Similarly, lift shall be measured from the centre of excavation to the centre of spoil heap.

(d) The normal rate is for each unit of 30 m lead and 1.5 m lift. For grater lead or lift, the rate shall be different for every unit of 30 m lead, and for every unit of 1.5 m lift.

(a) Unless otherwise specified, the foundation trench shall be measured in cu.m. for rectangular section, bottom width being width of concrete and the depth shall be measured as vertical depth even though the contractor might have excavated with sloping sides for convenience.

(a) Returning, filling and ramming excavated earth shall be taken in cu.m. under a separate item and shall include spreading in layers of 20 cm in depth, watering, ramming and leveling.

(a) Clay puddle work shall be taken in cu.m. and shall be described including supply of clay, its preparation, placing in layer of 15 cm, ramming, etc.

(a) Trimming and dressing of natural ground to remove vegetation and small irregularities not exceeding 15 cm deep shall be taken in sq.m. under a separate item ‘Surface Dressing’.

(b) Cutting down of trees exceeding 30 cm girth shall be accounted separately and enumerated i.e., taken in numbers, stating the girth at 1 m above ground and paid separately.

(a) Excavation exceeding 1.5 m in width as well as 10 sq.m. in plan but not exceeding 30 cm in depth shall be described as Surface excavation and measured in sq.m.

(a) When spring water requires pumping, the work of pumping and dewatering shall be taken under separate item.

(a) Timbering or ‘Planking and Strutting’ for protecting the sides of trench or loose earth, shall be measured in sq.m. of face supported, and shall be classified under separate items as: –

(b) Depth not exceeding 1.5 m,

(c) Depth exceeding 1.5 m but not exceeding 5 m,

(d) Depth exceeding 5 m.

(e) Timbering shall include all necessary timber work including walls, struts, poling boards, etc.

(f) Both sides of trench shall be taken as one side area and shall be equal to length x depth of timbering.

As per I.S. 1200 of 1974, the measurement of the item of earth work shall be carried out as follows: